Power Distribution Boxes: The Ultimate Guide to Enhanced System Efficiency and Performance

2026-01-09

In today's fast-paced industrial world, achieving optimal system efficiency and performance is more critical than ever. Enter power distribution boxes—those unsung heroes that streamline energy flow and minimize downtime. But how can you ensure your setup is truly optimized for peak results? Our comprehensive guide dives deep into the intricacies of these essential components, offering actionable insights to transform your operations. At Lugao, we're passionate about empowering businesses with cutting-edge solutions that go beyond the basics. Get ready to uncover expert tips and innovative strategies that set our approach apart, making this your go-to resource for elevating every aspect of your system. Let's explore how smart power management can drive your success.

Understanding the Basics of Power Distribution Boxes in Modern Systems

In modern electrical systems, power distribution boxes serve as the crucial link between the main power source and the various circuits that power our devices and appliances. They are essentially the hub where electricity is divided and directed to different parts of a building or system, ensuring that each circuit receives the appropriate voltage and current. Without these boxes, managing and controlling electricity flow would be chaotic and unsafe, as they house protective devices like circuit breakers and fuses that prevent overloads and short circuits.

Today's power distribution boxes have evolved significantly from their simpler predecessors, integrating advanced features to meet the demands of contemporary systems. For instance, in smart homes and industrial setups, these boxes often include digital monitoring capabilities, allowing users to track energy consumption in real-time or remotely control circuits via apps. This not only enhances efficiency but also supports sustainability efforts by identifying areas of waste. Moreover, modular designs have become common, enabling easy customization and upgrades without extensive rewiring, which is a game-changer for businesses adapting to new technologies.

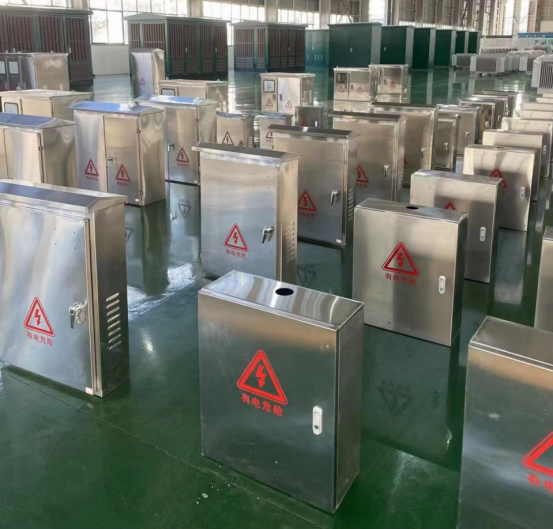

A key aspect that sets modern power distribution boxes apart is their emphasis on safety and reliability. They are engineered with robust materials to withstand harsh environments, such as moisture or extreme temperatures, making them suitable for diverse applications from residential to commercial settings. Additionally, features like ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs) are standard in many models, providing extra layers of protection against electrical hazards. By understanding these basics, users can better appreciate how these unassuming boxes play an indispensable role in keeping our power systems running smoothly and securely.

Key Features That Boost Efficiency and Reduce Energy Waste

Integrating smart sensors and automation systems allows for real-time monitoring and adjustment of energy usage, cutting down on unnecessary consumption. These tools track everything from lighting levels to equipment performance, ensuring that resources aren't wasted during idle periods. Imagine walking into a room that automatically dims lights when sunlight is sufficient—this is the kind of seamless efficiency modern technology offers.

Adaptive HVAC controls take temperature management to the next level by learning usage patterns and tailoring output accordingly. Instead of blasting air conditioning all day, these systems adjust based on occupancy and weather forecasts, maintaining comfort without excess strain. It's like having an intuitive thermostat that knows when to cool down or heat up, making spaces feel just right while slashing utility bills.

Energy recovery systems capture and repurpose waste heat or power from industrial processes, turning what was once lost into usable energy. This approach not only reduces emissions but also lowers operational costs by harnessing residual resources. Picture a factory where exhaust heat warms water for other tasks, creating a circular flow that maximizes every watt of electricity spent.

Practical Applications for Industrial and Residential Settings

In industrial and residential settings, advanced technologies like smart sensors and automation systems are no longer futuristic concepts but essential tools that enhance efficiency and safety. For example, in manufacturing plants, integrated IoT platforms can monitor equipment health in real-time, predicting failures before they cause costly downtime, while in homes, these same principles apply to energy management, allowing residents to optimize heating and cooling based on actual usage patterns. This seamless integration across different environments showcases how tailored solutions can address unique challenges, from reducing operational costs in factories to lowering utility bills for households.

Beyond mere functionality, these applications also foster a more sustainable and user-friendly experience. In industrial contexts, automated systems can significantly cut waste by precisely controlling material flows, whereas in residential areas, smart devices like water leak detectors or security cameras offer peace of mind by alerting homeowners to potential issues instantly. By focusing on adaptability and real-time responsiveness, these technologies bridge the gap between complex industrial needs and everyday convenience, making them invaluable for diverse settings.

Ultimately, the success of these practical applications lies in their ability to evolve with user demands and environmental shifts. Innovations such as AI-driven analytics in industrial robotics or voice-activated assistants in smart homes illustrate a trend toward more intuitive interfaces that reduce the learning curve. This holistic approach ensures that both large-scale operations and personal spaces benefit from enhanced control and reliability, positioning these solutions as cornerstones for modern, connected living and working.

Installation Tips and Best Practices for Optimal Performance

Getting your setup right from the start can make a world of difference in how everything runs down the line. Instead of just plugging things in and hoping for the best, a bit of planning goes a long way. First off, ensure you're working in a clean, stable environment—dust and vibrations might not seem like big deals, but they can quietly sabotage performance over time. Double-check that all components are compatible and seated properly; a loose connection now could lead to frustrating glitches later.

Many folks skip reading the manual, but those instructions often hide golden nuggets tailored to your specific model. Customizing settings based on your typical usage patterns, rather than sticking with defaults, can really boost efficiency. Keep cables organized and away from heat sources to avoid unnecessary wear, and don't forget about ventilation—good airflow prevents overheating and keeps things humming smoothly.

Lastly, think long-term by setting up a simple maintenance routine. Regularly updating software and checking for wear on parts might seem tedious, but it's cheaper than a major fix later. Test the system thoroughly after installation to catch any quirks early, and maybe even tweak a few settings to fine-tune performance. With these steps, you're not just installing—you're building a foundation for reliable, top-notch operation.

Maintenance Strategies to Ensure Long-Term Reliability

When aiming for long-term reliability, a proactive maintenance approach can significantly reduce unexpected downtime and extend the lifespan of equipment. Instead of waiting for failures to occur, organizations can implement predictive techniques such as vibration analysis, thermal imaging, and oil sampling to detect early signs of wear. This not only prevents costly repairs but also ensures that operations run smoothly over years, building a foundation for consistent performance and reduced operational risks.

Another effective strategy involves integrating condition-based monitoring with scheduled inspections. By combining real-time data from sensors with routine checks, teams can tailor maintenance activities to actual needs rather than fixed intervals. This dynamic method helps in identifying subtle changes in performance that might be missed otherwise, allowing for timely interventions that keep systems running optimally and avoid minor issues from escalating into major failures.

Furthermore, fostering a culture of continuous improvement and training among maintenance personnel is crucial for sustaining reliability. Encouraging teams to stay updated on best practices and emerging technologies empowers them to make informed decisions and adapt strategies as needed. This human-centric approach ensures that maintenance efforts are not just technical tasks but collaborative efforts that enhance overall system resilience and long-term dependability.

Future Trends and Innovations in Power Distribution Technology

Power distribution technology is evolving toward greater flexibility and resilience. One key trend is the integration of smart grid systems, which allow real-time monitoring and control of electricity flow. This enables more efficient management of renewable energy sources like solar and wind, reducing waste and improving grid stability. These advancements aim to create a more adaptive network that can handle increasing demand and environmental challenges.

Another innovation on the horizon is the use of digital twins for power distribution networks. These virtual models simulate physical systems, helping utilities predict failures, optimize maintenance, and test new configurations without risking actual operations. By leveraging data analytics, companies can move from reactive fixes to proactive strategies, enhancing reliability and cutting costs in the long run.

Additionally, the push for decentralized energy systems is reshaping how power is distributed. Microgrids and distributed energy resources allow localized generation and consumption, empowering communities and increasing resilience against outages. As these technologies mature, they promise a more democratized energy landscape, where users have greater control and sustainability becomes a core feature of distribution networks.

FAQ

They primarily manage and distribute electrical power from a single source to multiple circuits, ensuring safety through features like circuit protection and overload prevention while optimizing energy flow for efficiency.

Choosing a box with appropriate voltage ratings, capacity, and protective features reduces power losses, minimizes downtime from faults, and enhances reliability, leading to smoother operation and better overall system output.

High-quality enclosures made from corrosion-resistant metals like stainless steel or robust plastics, combined with secure sealing against dust and moisture, ensure longevity even in harsh environments.

Yes, modern boxes often include IoT sensors for real-time monitoring of power usage, remote control capabilities, and data analytics to predict maintenance needs and optimize energy consumption dynamically.

Compliance with international standards such as UL, IEC, or NEC is crucial, covering aspects like proper grounding, insulation, and clear labeling to prevent electrical hazards and ensure safe operation.

By enabling precise load balancing, reducing cable clutter and transmission losses, and integrating with energy management systems, they help cut operational costs and lower carbon footprints.

Neglecting regular inspections for wear, overloading circuits beyond capacity, and using incompatible components can lead to failures; instead, schedule proactive checks and follow manufacturer guidelines.

Tailoring features like number of outlets, special connectors, or mounting options allows them to fit unique setups in sectors like telecommunications, data centers, or renewable energy, enhancing functionality.

Conclusion

Power distribution boxes play a pivotal role in modern systems by efficiently managing electricity flow to various components. Understanding the basics involves recognizing their function in centralizing power distribution, which helps prevent overloads and ensures consistent performance. Key features, such as advanced circuit protection and energy monitoring capabilities, significantly boost efficiency and reduce energy waste. These features not only enhance system reliability but also contribute to cost savings and environmental sustainability by minimizing power loss.

In practical applications, power distribution boxes are essential in both industrial settings, where they support heavy machinery and complex operations, and residential environments, optimizing home energy use. Proper installation tips and best practices, including correct wiring and placement, are crucial for achieving optimal performance and safety. Maintenance strategies, like regular inspections and timely upgrades, ensure long-term reliability and prevent disruptions. Looking ahead, future trends and innovations in power distribution technology are driving the evolution toward smarter, more integrated systems that further enhance efficiency and adaptability in an increasingly digital world.

Contact Us

Contact Person: Doreen

Email: [email protected]

Tel/WhatsApp: 8618057712366

Website: https://www.liugaopower.com/